Source:- Wikipedia Welding is a manufacture cycle that joins materials, normally metals or thermoplastics, by utilizing high intensity to...

|

| Source:- Wikipedia |

Welding is a manufacture cycle that joins materials, normally metals or thermoplastics, by utilizing high intensity to soften the parts together and permitting them to cool, causing combination. Welding is particular from lower temperature strategies, for example, brazing and binding, which don't liquefy the base metal (parent metal).

The base metal is normally melted first, followed by the addition of a filler material to create a pool of molten metal (the weld pool), which cools to form a joint that, depending on the weld design (butt, full penetration, fillet, etc.), may be stronger than the base metal. To create a weld, pressure can either be applied alone, in combination with heat, or both. In order to prevent contamination or oxidation of the filler metals or molten metals during welding, a shield is also necessary.

To create a weld, pressure can either be applied alone, in combination with heat, or both. In order to prevent contamination or oxidation of the filler metals or molten metals during welding, a shield is also necessary.

Types of Welding

1.Gas welding

Oxyfuel welding, sometimes referred to as oxyacetylene welding, is the most popular type of gas welding. Although it is one of the oldest and most adaptable welding methods, its use in industrial applications has declined recently. For welding pipes and tubes as well as for repair work, it is still commonly utilised. The equipment is simple and reasonably priced, and it typically uses acetylene and oxygen to burn, producing a welding flame that is around 3100 °C (5600 °F) in temperature.

The flame makes welding high alloy steels easier, but because it is less concentrated than an electric arc, it causes delayed weld cooling, which can increase residual stresses and weld distortion. Metals are cut using a similar procedure known as oxyfuel cutting.

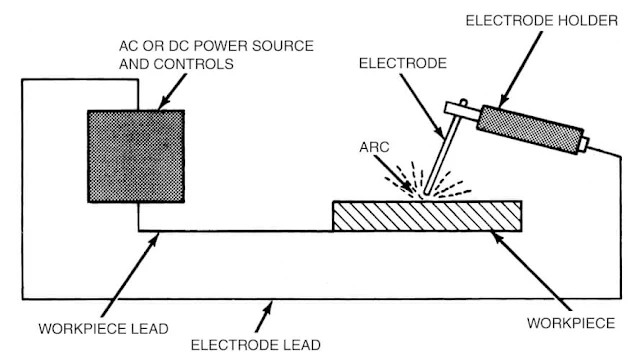

2.Arc welding

Shielded metal arc welding (SMAW), sometimes referred to as manual metal arc welding (MMAW) or stick welding, is one of the most used types of arc welding. The consumable electrode rod, which is made of filler material (typically steel) and is covered with a flux, is used to create an arc between the base material and the base material in order to protect the weld area from oxidation and contamination by producing carbon dioxide (CO2) gas during the welding process. A separate filler is not required because the electrode core itself serves as the filler material.

No comments